Cost reduction is today a more than ever important topic in the agendas of companies in the manufacturing, production and service sectors, and it is likely to continue like that for the coming years. Supporting this need technology has proved to be a powerful catalysts to achieve cost optimization; in this regard a new technology emerging from the integration of Advanced Analytical Digital tools with existing technologies, supporting process control and reliability, is making good progress, towards a next generation of reliability systems, aiming to achieve accurate and long range failure prediction.

Accurate failure prediction is an operational aspect with essential implications on operating costs. Elements such as spare parts inventory, Turn Arounds duration and scheduling, downtime reduction, defect elimination, are clear examples of such an influence.

The size of the prize for accurate failure prediction is in the order of magnitude of hundreds of millions of dollars, when calculated throughout the life cycle of an asset. Even more it may give a company the competitive edge to survive in a challenging economic environment.

This very relevant need to capture cost reduction opportunities is providing a fertile background, for introducing the mentioned technology, which is consolidating as an effective tool for failure forecasting.

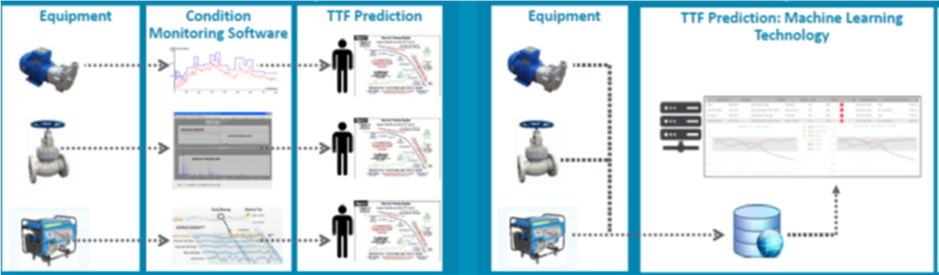

The technology uses 1) the computational power of Advanced Analytics Systems (AAS) combined with 2) the data capturing power of (existing) Real Time Data Acquisition Systems and 3) knowledge of failure mechanisms from Expert Systems, to configure a digital system able to predict, with a very good degree of confidence, the time when a machine, system or process may fail.

The prediction can be done over a certain period of time which depends on the size of the surveillance period.

Figure 1: The new technology complements effectively the current approach. Image Courtesy of VROC “Intelligent Asset Management”

Some cases have reported degrees of confidence in the range of 95%, which is considered enough for planning purposes.

This technology offers important competitive advantages in terms of integrated planning of operations and maintenance activities, as well as downtime reduction, optimization of spare parts inventory, and if combined with the right reliability and engineering skills, it may also help on running time optimization.

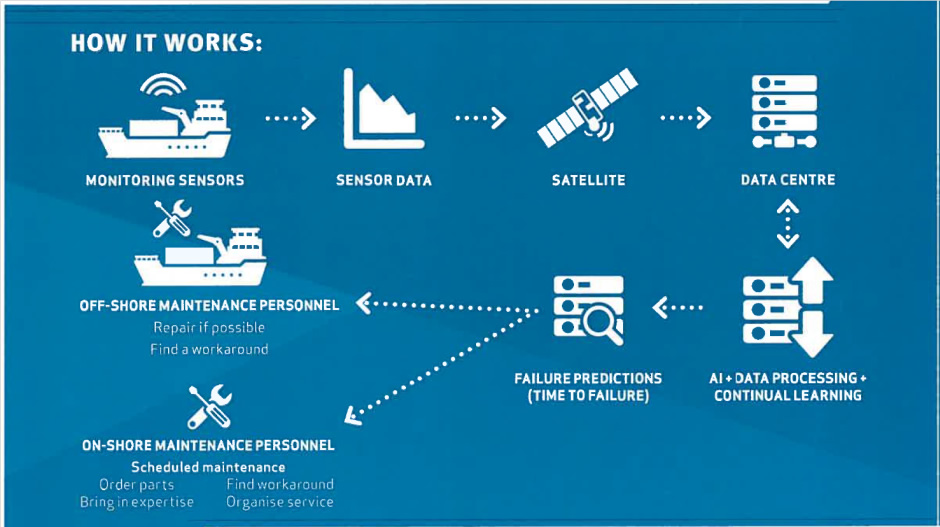

Applications in remote areas are of particular value given logistics and planning challenges, for example for mining, offshore operations, marine vessels, pipeline operations, and others.

From the stand point of downtime reduction the technology is attractive to operations where the cost of plant outages is high and has noticeable impact on revenue, such as mining, LNG plants, refineries, petrochemical plants and others

The schematic in Figure No 2, shows the concept of how the system is configured and how the data flows from the operational site, to the analysis centre for processing.

Figure 2: System integration, for a marine operation. Image Courtesy of VROC “Intelligent Asset Management”

The cost of implementation is low, considering that most of the infrastructure for data acquisition and transmission is already in place and the service for surveillance and failure prediction can be contracted for a monthly fee, which is flexible depending upon the size of assets to monitor.

Even further a service for reliability analysis and optimization can be contracted ad hoc. This helps operators to drop operating costs

by outsourcing these services and providing its contractors with a strong data foundation always necessary for effective reliability analysis.

Even beyond the resolution of a failure, the system enables proactive analysis of the failure root causes and possibly mitigate the degradation process, aiming to extend the running time to the next best opportunity to address the problem.

This evolved approach to assets reliability based on the powerful capabilities of Artificial Intelligence is capturing a lot of interest from a number of industrial sectors.

For more details please contact:

Mr. David Campbell at VROC Intelligent Asset Management, 200 Wellington Street, East Perth, WA, Australia, 6913, Phone +61 (0)439610177, +61 1300 256248 (Ext 121), e-mail: david.campbell@vroc.com.au.

Mr. Victor J. Torres at BRISK Ltda. Phone +57 3112379178, Carrera 76 No 170-40, Bogota, Colombia. E-mail: victor.torres@briskltda.com